Demanding industrial applications require utmost precision and secure technologies to safeguard them from influences that could ruin a project. These may include leakage from thermal vibration or pulsation within an application. In all cases, the operator’s safety and working environment are business-critical.

Senior project managers are often given many options when choosing fittings for instrumentation, process and control systems and other equipment. Users need a risk-free, leakage-free solution and simple enough to use without breaking the budget.

Compression fittings generally do just that. These fittings are generally used to connect two imperial tubes, two metric tubes or the connection of a metric tube to an imperial tube.

The common size range is between 1/8 to 2 inches / 4mm to 50mm. Compression fittings are rated to the optimal working pressure of the tubing it connects to.

Stainless steel compression tube fittings are used for various applications in different industrial settings. Twin ferrule is preferred for higher working pressures and harsh applications. This also makes twin ferrule fittings a safe choice for the full gamut of low-pressure operation right through high pressure. So, what are the main differences between the single ferrule and double ferrule tube fittings?

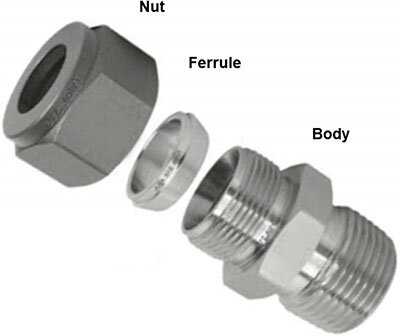

Single ferrule compression fittings

Single ferrule fittings have a comparatively lower pressure rating than their twin-ferruled counterpart. These compression fittings are designed considering the operators’ ease of use, having one less part than twin ferrule fittings and are generally difficult to install incorrectly.

Despite its benefits, double ferrule fittings are generally the preferred option.

Why are single ferrule compression fittings still used in the industry?

While the high-pressure rating and perfect connection of double ferrule fitting make them a favourable option in the industry, single ferrule compression fittings are slightly cheaper for low-pressure applications where there is no risk of pressures increasing or mistakenly mixing of the two suitable types.

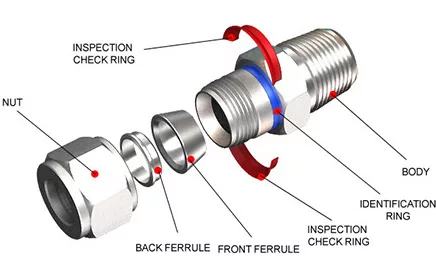

Double ferrule compression fittings

Double ferrule (or two-ferrule, twin-ferrule depending on the manufacturer) compression fittings are produced in various materials, but the size ranges are identical to single ferrule fittings. Double ferrule compression fittings provide a perfect connection thanks to its strong mechanical grip design. The fittings can be used for tubing with various thicknesses and hardness levels.

Design of double ferrule tube fittings

The basic design of a double ferrule tube fitting consists of four main pieces:

- Nut

- Front ferrule

- Back ferrule

- Body

Some very advanced fittings may have additional parts, such as a tightness indicator (such as the VIS-LOK Stainless Steel Compression Tube Fitting above).

Double ferrule compression systems are designed to give a tight grip around the tubing, minus any damage to the wall. The ferrule inside is designed to perform as the locking ferrule, while the outer ferrule provides its sealing capability.

Due to its robust design to withstand high temperatures, pressures and vibration levels, it is one of the best choices for applications within an industrial setting.

As Australia’s leading industrial pipe fitting supplier, we supply premium grade stainless steel compression tube fittings to industries with applications in:

- Oil and Gas Upstream

- Oil and Gas Downstream

- Industrial Gases

- Mining

- Power and Energy

- Research and Development in Universities

- Metal Processing

- Medical Gas Applications

- Natural Gas Distribution

- And much more