In recent years, press fit systems have emerged as a game-changing solution for streamlining piping installations.

Their ability to deliver reliable, efficient and cost-effective alternatives to traditional tube joining methods has made a significant impact across numerous industries. The results have been nothing short of transformative, offering a modern approach that meets the demanding needs of today’s industrial environments.

With exceptional material quality, innovative designs, proven reliability, and an extensive range of press fitting systems, Ibex Australia is at the forefront of this revolutionary technology.

This guide provides an in-depth overview of press fitting technology, covering everything you need to know – from how they work and their key advantages to best practices for installation.

What is a press fitting?

A press fitting is a cutting-edge piece of technology that uses a hydraulic press tool to join two pieces of pipe or tubing together. The metal-to-metal connection provides the mechanical link, while the sealing element ensures a watertight and airtight seal.

In press fittings, the sealing element is typically an O-ring made of high-quality materials like EPDM (ethylene propylene diene monomer), FKM (fluoroelastomer), or HNBR (hydrogenated nitrile butadiene rubber).

This O-ring is crucial to the fitting’s effectiveness. It sits inside the fitting and compresses when the hydraulic press tool is applied. The compression of the O-ring against the pipe or tubing creates a watertight and airtight seal, preventing leaks and ensuring the durability of the connection.

While traditional tube joining methods require heat-based equipment, press fit technology doesn’t. A specialised press tool is all you’ll need. This eliminates the risks associated with high temperatures and provides you with a faster installation, and a more secure connection.

How do press fittings work?

Press fittings work by creating a secure, leak-proof connection between pipes without the need for heat. This process involves using a battery-powered hydraulic tool along with specialised jaws and rings designed for the specific material being used.

The process involves inserting the pipe into the fitting, which contains a sealing element (like an O-ring) and a metal sleeve. The press tool then compresses the fitting, creating a secure, leak-proof connection by crimping the sleeve tightly around the pipe.

To give you a better understanding of how press fit technology works, here’s a simple, step-by-step breakdown of the process:

- Cut

Start by cutting the pipe to your desired length with a suitable cutting tool. Make sure the cut is straight and clean to provide a proper surface for the fitting. A precise cut is crucial for the integrity of the connection.

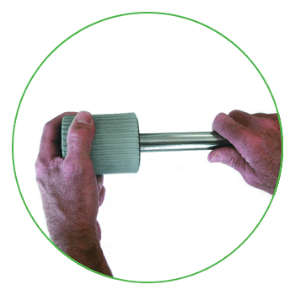

- Deburr

Next, use a deburring tool to deburr the cut ends of the tube both inside and outside. This step is important for removing sharp edges, burrs or debris that could potentially damage the sealing element or interfere with the fitting process. Having a smooth, deburred surface creates a secure and leak-free connection.

- Witness mark

Apply a witness mark on the tube at the appropriate insertion depth. This mark serves as a visual guide to confirm that the tube is fully inserted into the fitting during assembly.

- Assemble

Insert the tube into the press fitting until it reaches the witness mark, making sure it’s fully aligned and seated. The fitting contains an O-ring, which seals once pressed.

- Press

Using the appropriate pressing tool (along with an adaptor jaw and collar for larger sizes) securely press the fitting, creating a strong, leak-proof connection.

What are the main types of press fittings?

Ibex Australia offers an extensive range of press fittings, each precisely engineered to meet specific needs and applications, from high-pressure industrial settings to quick residential installations.

Here’s a detailed look at our different ranges of press fittings to help you select the most suitable one for your project requirements:

Tubepress Fittings

At Ibex Australia, we offer Tubepress fittings made in Germany, specifically engineered for high-pressure, demanding industrial applications. Backed by a manufacturer guarantee of up to 40 bar, these fittings are renowned for their extreme durability and reliability in handling various fluids and gases.

Tubepress fittings are ideal for applications such as extracting and transporting oil and natural gas in high-pressure pipelines. They’re also an excellent choice for water treatment and distribution, including filtration and pumping stations.

Key features of our Tubepress system

- High-pressure rating: Engineered to withstand up to 50* bar pressure, making them suitable for high-stress environments.

- Material compatibility: Versatile in accommodating different pipe sizes, from 15mm up to 168.3mm in diameter, making them ideal for both small-scale and large-scale projects.

- Durability: Constructed from high-quality materials that resist corrosion, temperature extremes and high pressures, making them extremely durable. To further reinforce this reliability, Ibex offers a 30-year tightness guarantee.

- 3-level press technology: Tubepress features a 3-level press system that provides maximum security at every joint. This advanced technology provides an added layer of reliability, significantly reducing the risk of leaks and ensuring a superior connection throughout the entire system.

- 316L stainless steel construction: Tubepress fittings are made from 316L stainless steel, known for its exceptional durability and resistance to corrosion. This premium material makes Tubepress fittings ideal for use in environments where long-term performance and minimal maintenance are critical.

- Easy installation: Designed with efficiency in mind, Tubepress fittings offer a straightforward installation process that reduces labour time and costs. Their user-friendly assembly makes them an ideal choice for quick and hassle-free pipe connections.

Technical specifications of our Tubepress system

- Material: Engineered from 316L stainless steel, known for its superior corrosion resistance and durability.

- Pressure Rating: Designed to handle pressures up to 50 bar (230 psi), depending on the pipe size and material.

- Temperature Range: Suitable for temperatures ranging from -20°C to 110°C (-4°F to 230°F).

- Standards: Complies with international standards such as ISO 9001 for quality management systems and relevant industry standards for pressure equipment.

- Sealing Technology: Features an EPDM or FKM sealing element for a reliable, leak-proof connection.

Impress Fittings

We have skillfully engineered our Impress Fittings to provide a secure and reliable connection with advanced sealing technology. Impress Fittings are crafted from durable 316L stainless steel, and their precision and versatility make them an excellent choice for handling a wide range of applications, including:

- Transporting natural gas, fuel oil, and other hydrocarbons in upstream, midstream, and downstream operations.

- Transferring corrosive chemicals, acids, and other hazardous fluids.

- Providing leak-free, secure connections in potable water pipelines.

- Managing the flow of water through various filters and treatment stages.

- Safely transporting fluids and gases in pharmaceutical laboratories and facilities.

- Creating strong, leak-proof connections to handle high-pressure fluids in hydraulic systems.

- And dozens of other practical applications for different project needs.

Key features of Impress Fittings

- Enhanced Sealing: Impress fittings are equipped with advanced two-level press technology, which provides an exceptionally tight and reliable seal. This dual-stage pressing ensures that the fitting clamps securely onto the pipe, effectively preventing any leaks.

- Pressure rating: We engineer our Impress fittings to handle high-pressure environments, with our standard pressure ratings up to 16 bar (approximately 230 psi), and high-pressure ratings up to 25 bar (approximately 360 psi).

- Two-level press technology: Impress fittings feature a unique two-level press design that ensures an even and secure connection at both stages of the pressing process. This dual-stage approach enhances the fitting’s overall integrity and performance, providing an additional layer of security and reliability.

- Premium 316L stainless steel: We construct our Impress fittings from 316L stainless steel, making them highly resistant to corrosion and wear. This provides superior durability and an ability to withstand harsh environmental conditions and chemical exposure.

- Ease of installation: The design of Impress fittings allows for simple installation without the need for hot works or extensive preparation. This simple method helps you save time and reduce your labour costs.

Technical specification of our Impress fittings

- Material: Designed from 316L stainless steel.

- Temperature Range: Operates effectively within a temperature range of -20°C to 120°C (-4°F to 248°F).

- Standards: Meets standards such as ISO 9001, and industry-specific standards for pressure and safety.

- Sealing Technology: Equipped with high-performance sealing elements designed for durability and leak prevention.

Impress Large Bore Fittings

Impress Large Bore Fittings are tailored for applications involving larger tube diameters. Perfect for high-rise buildings, these fittings excel in large-scale heating, ventilation, and air conditioning (HVAC) systems, where large bore pipes are necessary to efficiently distribute chilled or heated water.

They’re also highly suitable for use in oil and gas pipelines, where large bore connections are needed to handle the high flow rates and pressures involved in transporting oil, gas, and other hydrocarbons.

Whether you need reliable large bore piping systems for water systems, municipal supply networks, fire protection, or specialised uses like oil and gas pipelines, Ibex’s Impress Large Bore Fittings are tested and proven, making them your ideal choice.

Key features of Impress Large Bore Fittings

- Large Diameter Capability: Our Large Bore fittings are designed to accommodate large pipes, ranging from 49 mm to 168.3 mm in diameter. This makes them suitable for major infrastructure projects such as municipal water systems, large-scale industrial installations, and heavy-duty pipelines.

- High Strength: We engineer our Large Bore fittings to provide robust connections that can handle significant flow rates and high pressures. For example, with pressure ratings of up to 25 bar (approximately 360 psi), these fittings ensure reliable performance even under demanding conditions.

- Durability: Constructed from premium 316L stainless steel, Ibex’s Large Bore fittings are built to endure the rigours of large-scale industrial applications. This durability means fewer replacements and repairs, leading to significant long-term cost savings and a more reliable piping system.

- Simple installation: We design our Large Bore fittings to provide our customers with a straightforward installation. The advanced two-level press technology ensures that fittings are securely clamped onto the pipe with minimal effort. This simplicity speeds up the installation process, eliminates the need for hot works and reduces both labour time and costs.

Technical specifications of our Impress Large Bore fittings

Material: Made from stainless steel 316L for enhanced strength and durability.

Temperature Range: Suitable for a wide temperature range from -20°C to 150°C (-4°F to 302°F).

Standards: Adheres to international standards for large bore fittings, including ISO 9001 and specific standards for large-diameter press fittings.

Sealing Technology: Uses robust sealing elements to ensure secure connections and reliability under high pressure.

Express Fittings

We design our Express Fittings for quick installation and efficiency. Because they offer a reliable connection with a focus on speed, they’re a great choice for projects that require a rapid setup.

For example, residential plumbers can use Express Fittings to quickly connect pipes in bathroom renovations, rapidly install or upgrade kitchen plumbing systems or swiftly connect water heaters to a home’s plumbing system.

Express Fittings are also perfect for emergency plumbing repairs in homes, as they allow for fast and secure fixes to leaks or burst pipes.

Key features of Express Fittings

- High-pressure rating: We engineer our Express Fittings to handle demanding pressure environments, making them highly suitable for a wide range of applications. For instance, our standard pressure rating for Express fittings is up to 16 bar (approximately 230 psi). For higher pressure needs, they are capable of handling up to 25 bar (approximately 360 psi).

- Advanced sealing technology: Our Express Fittings utilise advanced sealing mechanisms to ensure a leak-proof connection. The integration of a robust O-ring or sealing element within the fitting provides a reliable and tight seal, preventing any leaks and ensuring system integrity.

- Fast installation: Each of our Express Fittings is engineered with user-friendly installation in mind. The fittings feature a straightforward, intuitive press mechanism that simplifies alignment and ensures quick, efficient installations, minimising project downtime.

- Versatility: Suitable for a wide range of applications, such as water distribution systems, compressed air systems, heating systems and fire protection systems, to name a few.

Technical specification of our Express fittings

- Material: Designed using stainless steel 304L.

- Temperature Range: Designed to operate within temperatures from -20°C to 110°C (-4°F to 230°F).

- Standards: Complies with ISO 9001 and relevant industry standards for pressure and material performance.

- Sealing Technology: Features advanced sealing technology for secure, leak-proof connections.

Epress Fittings

Epress is a cutting-edge stainless steel conduit system, engineered without the need for welding, specifically for electrical and data installations in challenging industrial settings.

For example, an automotive manufacturing plant could use the Epress system to protect and convey electrical and data cabling. Its stainless steel construction ensures long-term durability and offers robust resistance to chemicals, high temperatures and heavy wear and tear, making it highly suitable for the demands of manufacturing environments.

Epress is also ideal for processing facilities in the food and beverage industry, where hygiene and safety are paramount. For instance, its stainless steel construction resists corrosion and withstands frequent washdowns and exposure to harsh cleaning chemicals. This makes Epress an excellent choice for protecting electrical and data cabling in areas with stringent cleanliness requirements, such as dairy processing, breweries, or bottling plants.

Key features of Epress Fittings

- Cutting-edge press technology: Epress fittings feature a sophisticated press-fit technology that simplifies the installation process. This allows for quick and efficient setup, saving valuable time and greatly reducing labor costs. Its ease of installation is particularly advantageous for complex electrical and data conduit projects, where efficiency and reliability are paramount.

- Pressure ratings: Our Epress fittings are engineered to meet the rigorous demands of industrial electrical installations. For example, our standard pressure rating for Epress fittings is up to 10 bar (approximately 145 psi), and our high pressure rating is up to 16 bar (approximately 230 psi).

- High-grade 316L stainless steel: Constructed from 316L stainless steel, Epress fittings offer exceptional durability and corrosion resistance. This premium material is specially selected to endure harsh environmental conditions, making it ideal for electrical and data installations in challenging industrial settings.

Technical specifications of our Epress fittings

- Material: Made from high-quality 316L stainless steel.

- Temperature Range: Effective within a temperature range of -20°C to 120°C (-4°F to 248°F).

- Standards: Meets ISO 9001 standards, along with specific industry requirements for performance and safety.

- Sealing Technology: Incorporates high-quality sealing elements to ensure reliability and prevent leaks.

Why choose Ibex Australia’s press fit systems?

At Ibex Australia, we have more than 30 years of experience delivering premium stainless steel piping solutions to a wide range of industries. This has led to a comprehensive understanding, supported by real-world experience and scientific data, of what it takes to deliver our customers with the best possible piping solutions.

Our large range of press fit systems, which include the Tubepress, Impress, Impress Large Bore, Express and Epress fittings, represents a significant advancement in jointing technology. These systems stand out due to their innovative features, ease of installation, cost savings, durability, and versatile sizing options, setting a new standard in the industry.

Here’s a detailed look at five unique benefits you can expect from Ibex Australia’s press fit systems:

- Superior durability and corrosion resistance

At Ibex Australia, we craft our press fit systems from high-quality stainless steel, offering you exceptional durability and resistance to corrosion. This makes them ideal for environments where exposure to moisture, chemicals or other corrosive substances is common, providing you with a long-lasting and reliable connection.

For example, piping systems in chemical processing plants are regularly exposed to high-pressure steam and corrosive chemicals. Ibex’s stainless steel press fit systems are perfect in environments like these. Our press fittings maintain their integrity without cracking, leaking or corroding, even in temperatures that fluctuate drastically from extreme heat during operation to cooler conditions during shutdowns. This exceptional reliability ensures the safety and efficiency of your entire system.

- Quick and straightforward installation

Press fitting is a remarkably innovative method. Because it doesn’t require heating equipment, the process is significantly faster and more straightforward, allowing you to connect pipes in a fraction of the time it traditionally takes to heat and join pipes.

Press fitting’s quick and simple installation process can also save you a significant amount of time, making them ideal for projects with tight deadlines.

For example, in a commercial building project with a tight schedule, Ibex’s press fit systems enable quick piping installation without welding or soldering, significantly speeding up the process and keeping the project on track.

- Multiple applications for different industries

Ibex’s press fit systems are compatible with various materials, including stainless steel (304L and 316L), carbon steel and black iron. This versatility makes them suitable for a broad range of industries and applications, from water and gas distribution to hydronic heating and fire protection.

To further highlight this versatility, you could use Ibex’s press fit systems for:

- Distributing water and gas in a residential complex.

- Installing hydronic heating systems in office buildings.

- Installing fire protection systems in industrial warehouses.

- Installing clean, sterile pipes for pharmaceutical water systems.

- Providing safe, corrosion-resistant piping for transporting non-consumable fluids in production lines, such as cleaning agents or cooling water.

- And so much more!

- Leak-proof and secure connections

We design all of our press fittings with advanced sealing technology, ensuring a watertight and airtight seal. The robust design of these fittings allows them to perform exceptionally well under high-pressure conditions. This makes them a supremely reliable choice for critical applications where failure is not an option.

For example, in an offshore oil rig, Ibex’s press fit systems are used to handle high-pressure fluid transport, where the advanced, airtight design ensures that the fittings maintain a secure connection.

- Cost-effective solution

Our press fit technology is remarkably efficient. The simple installation process not only saves time, but also significantly lowers labour costs, requiring fewer specialised skills than traditional pipe joining methods.

What’s more, because our press fit systems are extremely durable and corrosion-resistant, they require fewer maintenance checkups and provide a longer service life. Over time, this will offer you tremendous cost savings, making Ibex’s press fit systems a highly economical choice for both small- and large-scale projects.

What are some challenges with press fitting systems?

By now, you’re likely well-acquainted with the numerous advantages that press fitting systems offer over traditional joining methods. However, it’s equally important to be aware of some potential challenges. Understanding these challenges will ensure you’re fully prepared to maximise your experience with press fit technology.

- Specialised tools and training

Press fit systems require specific tools for proper installation, such as a battery-powered hydraulic press and custom jaws or rings. Without these tools, you won’t be able to achieve reliable and secure connections.

Press fit systems also require specific training to use the tools correctly and ensure a secure fit. Improper use of press tools or incorrect tube preparation can cause leaks or weak connections, or even damage to the tools themselves.

- Compatibility issues

Press fit tools and fittings are often material-specific. This means that different jaws and rings are required for different pipe materials like copper, PEX or stainless steel.

- Difficult to modify after installation

Once a press fit connection is made, it is permanent and cannot be easily modified or adjusted without cutting the pipe and installing a new fitting. This lack of flexibility can be a drawback in situations where adjustments need to be made after installation.

How does Ibex Australia eliminate these challenges?

Although some press fit systems can come with a few challenges, there’s no need to worry – Ibex Australia has a solution for each. Here’s how we address them:

- High-quality, easy-to-use tools and professional guidance

Ibex offers a range of high-quality, durable hydraulic press tools designed for various applications. We provide guidance on selecting the right tools for your needs, making sure you get the best value for your investment.

Our expert team also offers comprehensive training programs for your team, covering the proper use of press fit tools and installation techniques. What’s more, we provide detailed user guides, manuals and ongoing support to help your team get up to speed with press fit technology.

That’s not all! We also have an experienced support team available to answer any press fitting questions or concerns you have.

- Versatile range to minimise compatibility issues

Ibex’s press fit systems, including Tubepress, Impress and Express fittings, are designed to work with a wide variety of materials and pipe sizes. Our extensive product range minimises compatibility issues and simplifies inventory management.

Additionally, we provide expert advice on selecting and using the right fittings and tools for your specific applications.

- Planning and designing systems

While press fit connections are relatively permanent, Ibex has a team of technical experts you can rely on for advice to ensure you have a system that fits your needs perfectly. Our experts are more than happy to help you choose the right system and fittings to meet both your current and potential future needs.

How do major industries benefit from using Ibex Australia’s press fit systems?

At Ibex Australia, we have proudly served a variety of key industries for over 30 years. Here are some major industries who turn to us for our precisely engineered press fit systems:

Chemical processing

In chemical processing, press fit systems are used for handling corrosive chemicals and aggressive fluids. The advanced stainless steel construction of Ibex’s fittings provides excellent resistance to chemical attack, ensuring long-term durability and reliability.

Leak-proof connections are crucial in chemical processing for preventing hazardous spills. Ibex’s advanced sealing technology in press fittings offers secure, leak-free joints that help in maintaining a safe working environment.

Oil and gas

The oil and gas industry often requires piping systems that can withstand high pressures and harsh environments. Ibex’s press fit systems are designed to handle such conditions, providing strong and reliable connections for pipelines and equipment.

Additionally, the quick and straightforward installation process of press fit systems allows oil and gas companies to reduce labour time and enhance operational efficiency.

Water treatment

In water treatment facilities, press fit systems are used for transporting clean water and dealing with wastewater. The durability of Ibex’s fittings ensures they can handle varying water pressures and flow rates without compromising performance.

Because our high-quality stainless steel fittings are corrosion-resistant, they’re particularly valuable in water treatment applications where exposure to water and chemicals is constant.

Construction

In the construction industry, press fit systems have become a go-to solution for plumbers working on both residential and commercial installations. The primary appeal of our press fit systems lies in their speed of installation. With the ability to install press fittings quickly and efficiently, plumbers can accelerate the pace of their work, contributing to faster project timelines.

What’s more, because our press fit systems eliminate the need for open flames or hot works, they have greatly enhanced job site safety. This is a significant advantage in construction environments where safety regulations are stringent and minimising risks is a top priority.

Food and beverage

Although Ibex’s press fit systems are not used for transporting food or direct liquids, they play vital roles in other areas of the food and beverage industry, including:

- Supplying potable water for various operational needs, such as equipment cooling, cleaning and general facility maintenance.

- For compressed air lines, Press fittings are used to power pneumatic equipment and automation processes within food and beverage facilities. The reliable sealing and pressure ratings of press fittings help maintain consistent air pressure, essential for efficient equipment operation.

- In managing wastewater and drainage, press fittings are used in plumbing systems that transport effluent away from production areas. The corrosion-resistant properties and ease of installation make our press fit systems ideal for handling the various waste streams in food and beverage facilities.

Press fit case study examples

Ibex Australia’s press fitting systems have provided successful outcomes for a range of projects across industries. Here are some examples highlighting how our clients have benefited from using press fit systems in their projects:

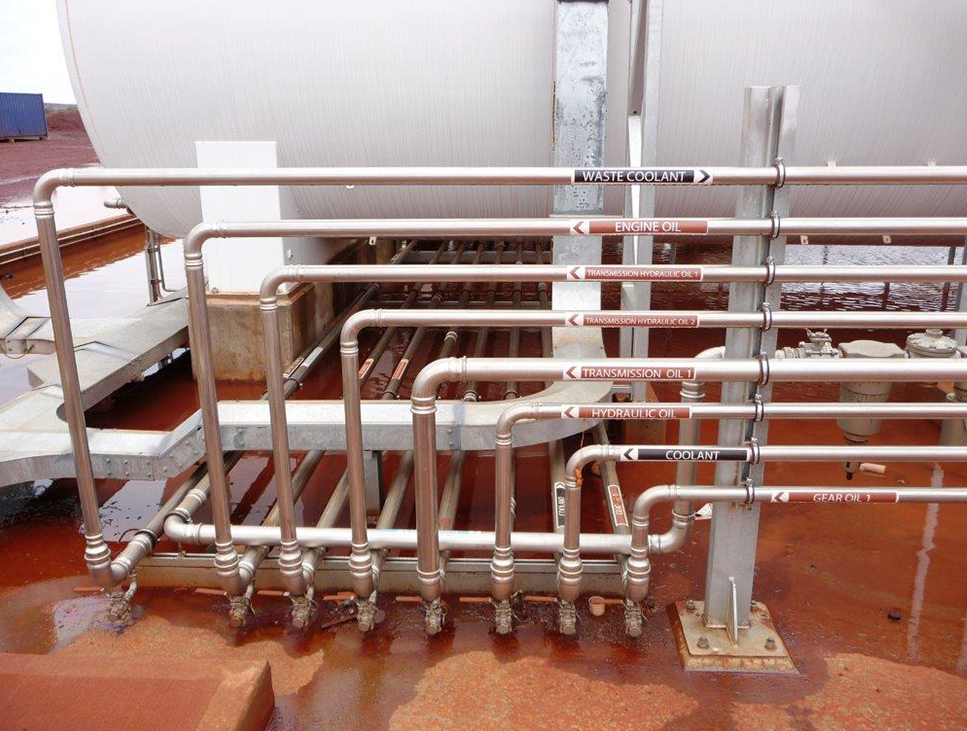

International Fuel Equipment & Services (IFES)

IFES is an Australian, family-owned and operated company specialising in hydrocarbon storage and quality engineering services.

IFES was approached by a customer needing a rapid turnaround for a bulk fuel tank project. To meet the tight deadline, they determined that press fit fittings would expedite the process by eliminating welding and hot work permits, offering a 10x faster installation compared to welding, and ensuring a more secure and cost-effective solution.

By using Ibex Australia’s Impress 316L stainless steel press fit tubes and fittings with Viton seals, the need for welded fittings was eliminated. This choice halved the build time and resulted in an excellent final product.

Berrigan Shire Council

When looking for an efficient system for town water rectification works, Berrigan Shire Council partnered with Ibex Australia to utilise our stainless steel press fit tubing.

The partnership between Ibex Australia and Berrigan Shire Council led to the successful installation of Impress 316 Stainless Steel Press Fit Systems.

Our innovative impress system enabled the council to complete several projects, including town water main rectification, Amaroo Residential Units construction, a wash station in Berrigan, and tank relocation and metering at the Finley WWTP.

Explore Ibex Australia’s range of press fitting systems

Ibex Australia’s press fitting systems are your go-to solution for fast, reliable and cost-effective piping installations.

Simplify your projects by leveraging the performance and longevity of Ibex’s press fitting systems. With versatile fitting options, significant cost savings, reduced labour costs, and effortless installation—without the hassle of hot works—the benefits with Ibex are limitless.The future of tubing installations is with Ibex. Don’t settle for outdated methods – upgrade to a press fit solution engineered to last. Explore our range of press fittings and contact our technical support team for expert advice.