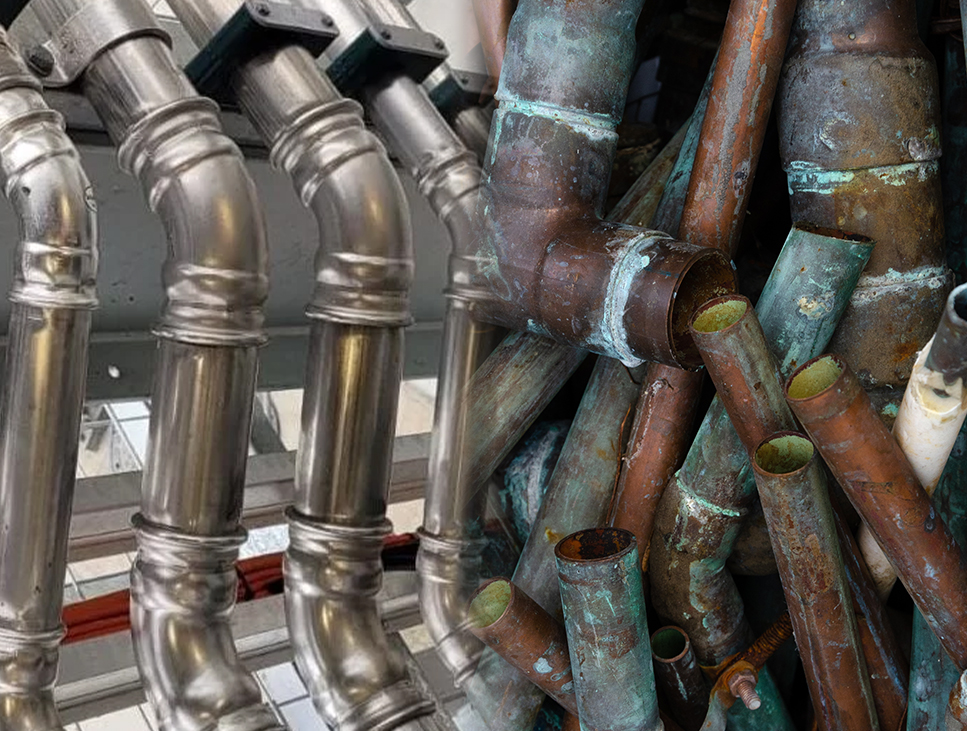

Plumbers around Australia have always opted towards copper as their choice for piping. With copper prices continuing to soar since the end of 2023, plumbers are now seeking materials that are both cost efficient and reliable. Switching to stainless steel press fit from traditional copper now makes more sense than ever, as stainless steel is competitive in price and provides superior durability and performance.

There have been so many advancements in recent years within the stainless steel press fit industry, which makes it a viable option for piping solutions in both residential and commercial applications.

Why should plumbers be considering stainless steel as an alternative to copper?

- Cost Effective

Stainless steel offers superior corrosion resistance, that ensures a smart investment and long-term savings in maintenance. Stainless steel also has improves flow rates that allow for a downsizing of pipe runs, that equals a reduction of material and installation costs. - Labour and Installation Time

Stainless steel tube is lighter and easier to handle, and requires no special training or skills to install. It’s also incredibly strong and durable with a higher tensile rate, which leaders to fewer supports required – as much as 40% fewer clips. - Corrosion Resistance

Stainless steel is ideal for harsh environments, such as coastal cities, as it offers superior corrosion resistance than copper that ensures long-term performance for all kinds of applications. - Price Stability

As opposed to the fluctuating prices of copper, stainless steel is a stable priced commodity due to its nickel reliance. This allows project stability and reduces unexpected costs – providing a more predictable option when quoting for projects in advance. - Versatile Size and Application

Stainless steel comes in a large range of sizes – up to 6 inches – and is suitable for a wide range of applications. Stainless steel is also compatible with O-rings for water, LPG, natural gas, steam, hydrocarbons and compressed air. The versatile nature of stainless steel allows plumbers to use one material across different systems in their project, reducing inventory and costs.

When thinking about copper pipe vs stainless steel pipe, there are many features that make stainless steel superior to copper.

| Features | Copper Pipe | Stainless Steel Pipe |

| Maximum pressure rating | Up to 16 bar | Up to 50 bar |

| Velocity effects on corrosion | Very high | Minimal effect |

| Sizing | Up to 4-inch press fit | Up to 6-inch press fit |

| Susceptible to theft | Very high | Low |

| Stable pricing | No | Yes |

| Durability | Low durability | High durability |

How Ibex Australia Can Help

Ibex Australia’s 316L stainless steel press fit systems provide superior versatility, strength and corrosion resistance compared to copper. Our Tubepress and Impress 316L stainless steel press fit systems are both European-manufactured, can suit up to 50* bar pressure rating, and are WaterMark and Gas approved.

Our Express 304L press fit system is a more durable and robust system than copper, and even aluminium, and can handle up to 40* bar pressure rating.

Ready To Make The Switch?

Ready to upgrade from copper to stainless steel piping systems for your next project? Send us your existing copper quote, and we can quote the same products in stainless steel.