In the pursuit of a sustainable energy future, hydrogen has emerged as a crucial player, offering a versatile, clean, and sustainable energy source for applications in many industries and in transportation. Ibex Australia can offer our H2 Ready Certified Tubepress® Stainless Steel Press Fit System and VIS-LOK® Stainless Steel Compression Fittings for use in hydrogen applications.

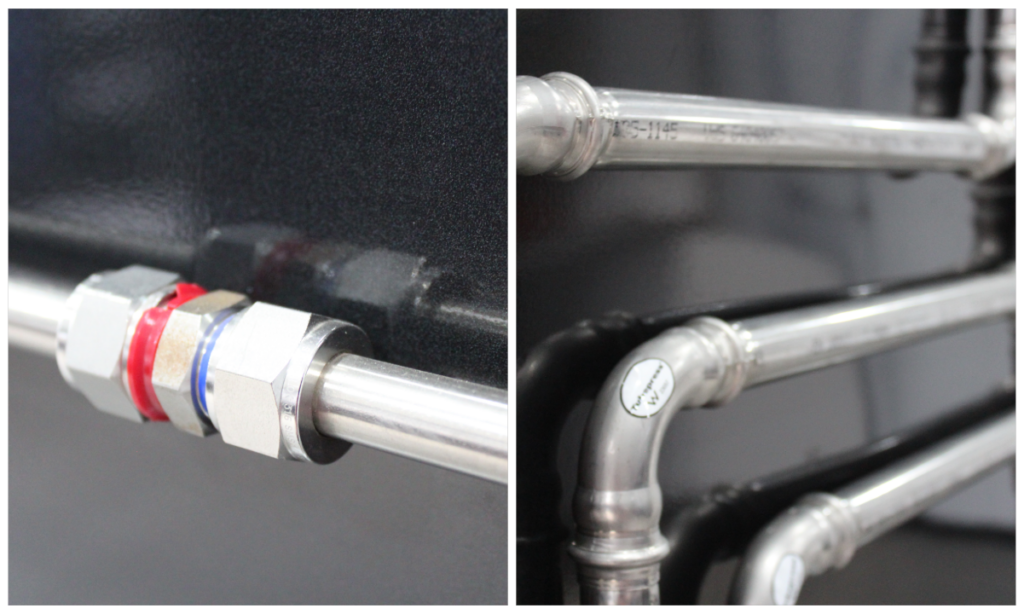

Safety is paramount in transporting hydrogen. Ibex Australia’s Tubepress Stainless Steel Press Fit System includes fittings and tubes made of the premium 1.4404 grade 316L stainless steel, providing exceptional corrosion resistance with a high molybdenum content and low carbon content. This system, available up to 108 mm dimensions, facilitates the fast, safe and environmentally friendly installation of pipework in hydrogen projects, with the H2 Ready Certification issued by DBI-Gastechnologisches Institute in Freiberg, Germany, offering assurance of suitability for systems containing up to 100% hydrogen.

Our VIS-LOK Stainless Steel Compression Fittings and seamless stainless steel tube are made from high-quality 316/L stainless steel. The VIS-LOK compression fitting’s patented check ring system ensures a perfect connection every time. These fittings have been installed and proven in large scale hydrogen projects across the globe.

Ibex Australia not only ensures safe hydrogen transport today but also offers futureproofing for tomorrow. The adaptability of our Tubepress and VIS-LOK systems allows for the transportation of natural gas and hydrogen — without the need for pipeline replacements.

Embrace sustainability today with Ibex Australia and be prepared for the hydrogen-powered future.