Compression fittings are a popular choice for tube connections in industrial applications, and for good reason. They provide a proven, reliable connection and the ability to install them without the need for specialised tooling. VIS-LOK® Compression Fittings are designed to make correct installation even simpler, ensuring a perfect connection between fitting and tube every time. Compression fittings in general consist of three main parts: a compression nut, a compression ring or rings (also known as ferrules), and a fitting body. The compression nut is typically made of brass or stainless steel and is threaded onto the fitting body, with the compression ring/s contained between the fitting body and the compression nut. The nut and ferrule/s are placed over the tube before the tube is inserted into the fitting body. In addition to these parts the VIS-LOK® range of compression fittings also has a patented ‘check ring’.

To make the connection, the compression nut is tightened onto the fitting body, compressing the ferrules which in turn bite into the surface of the tube, creating a seal and gripping the tube simultaneously. This connection results in a joint that is impervious to leaking and is suitable for high pressure applications. Because compression fittings are easy to install and require no soldering or welding, they are a popular choice for many work sites and facilities as they reduce installation time and remove the health and safety concerns around hot works.

One of the advantages of VIS-LOK® stainless steel compression fittings is that they can be used on a variety of pipe materials, including stainless steel and copper tube, and polyurethane and nylon hose. This makes them a versatile choice for projects where you may need to connect different types of pipes. Compression fittings can be easily removed and the fitting body and compressor nut can be reused if you need to make changes to your system. The ferrule/s will need to be replaced, as they are distorted during the connection process.

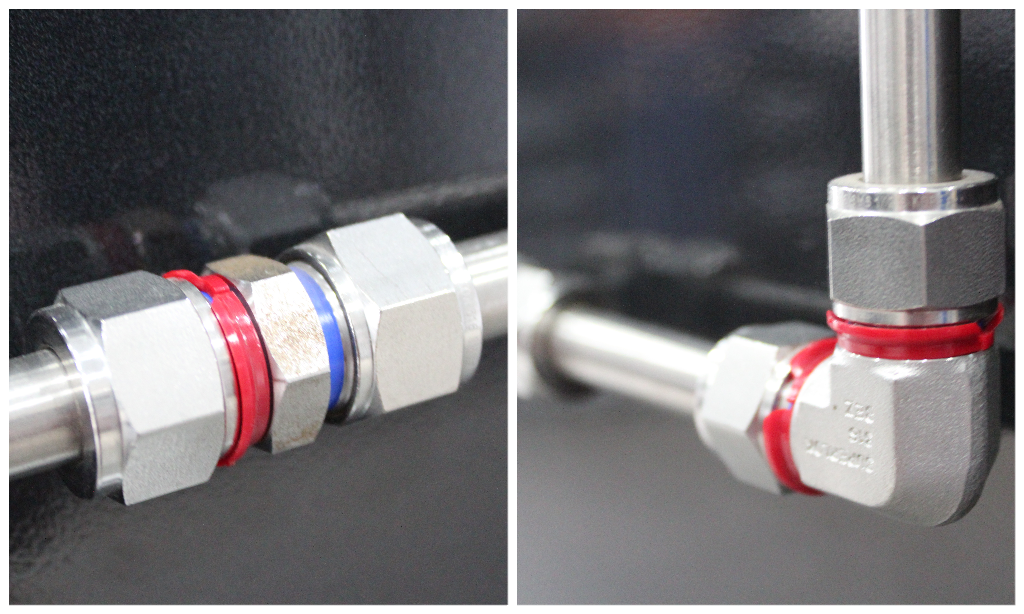

A brilliant advantage of VIS-LOK® compression fittings are their patented check rings which make it very simple to ensure a perfect connection is achieved on every joint. Simply insert tube into the fitting fully, and finger-tighten the nut. Then use the appropriate tools to tighten the nut further, until the red check ring snaps off – your fitting is now at the correct tightness. This system prevents under tightening and over tightening of the compressor nut, both of which can lead to leaks in a compression joint.

When deciding whether to use VIS-LOK® compression fittings, there are a few factors to consider. First, consider the application, specifically the medium, working pressure and working temperature, then think about the materials you’ll be working with and whether compression fittings are compatible with them.

If you do decide to use VIS-LOK® compression fittings, there are a few tips to keep in mind. First, make sure you choose the right size compression fitting for your tube. This is critical as compression fitting tolerances are very tight. Additionally, be sure to use a compression ring that is designed for your specific tubing material. This will help prevent damage to the tube and ensure a secure connection. VIS-LOK® is also available in NPT and BSP threads, so please ensure the correct thread type is selected.

In conclusion, VIS-LOK® compression fittings are a popular choice for connecting pipes in a variety of projects. They are easy to install, versatile, and proven over many years. It’s important to consider the specific needs of your project before deciding to use VIS-LOK® compression fittings – be sure to choose the right size and type of fitting and consider the project as a whole to ensure a tight, leak-free connection every time.

To speak to one of our experts about using VIS-LOK® Compression Fittings in your project,